TESTING PHASE

Testing plays a vital role in our development process to ensure both reliability and accuracy. We prioritize parallel development and testing to identify and address issues early. By utilizing SITL and HITL simulations, we validate system performance, verify hardware integration, and fine-tune components before moving to physical trials, enhancing overall efficiency and safety.

Control systems testing

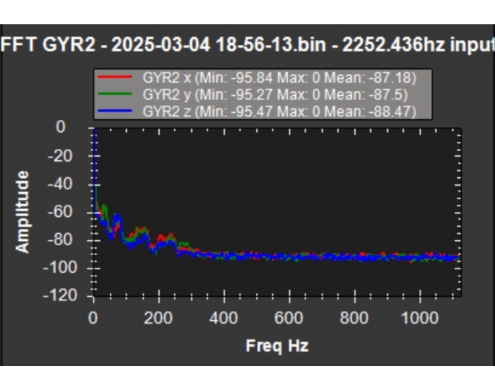

Multiple high-speed tests are conducted to assess the frame’s stability under mission conditions, confirming minimal wobbling, pitch angles under 30 degrees, and stable positioning. Additionally, sensor accuracy (including GPS, barometer, accelerometer) and EKF[7] position estimates are validated to ensure reliable navigation, and a stable cruising speed of 22 m/s is achieved. Internal noises and mechanical vibrations are identified through an FFT-based analysis and eliminated using Harmonic Notch Filters.

Communication System Testing

The communication systems were tested by monitoring signal strength, connectivity range, data throughput, and packet loss as the UAV traveled away from the ground station, ensuring stable and reliable data transmission for mission operations.

| Hardware | RFD900+ |

|---|---|

| Range | 1200m |

| Average Throughput | 741 Bytes/s |

| Average Packet Loss | 12% per 100m |

Table I: RFD Throughput And Packet Loss

| Distance to Home (m) | Packet Loss | Bytes/s | Packets/s |

|---|---|---|---|

| 400 | 1762 | 982 | 25 |

| 800 | 4938 | 1.94k | 57 |

| 1200 | 7961 | - | 0 |

Table II: Rx Tx Throughput And Packet Loss

Multiple range tests were conducted to test connectivity between the 5GHz PowerBeam M5 and Bullet M5. Sample images were transferred from the ground station through the powerbeam to the bullet on the UAV via SCP, while monitoring data transfer speed and connection strength at different distances. The results guarantee a consistent data transfer rate of 1MB/second at a distance of 380 feet between operators and the search grid.

| Distance from Home (meters) | Throughput (Kilobytes/sec) | Packets Sent/Received (datagrams) |

|---|---|---|

| 750 | 4000 | 721/721 |

| 1000 | 850 | 436/436 |

| 1250 | 300 | 740/740 |

Table III: 5GHz Connection Test Results

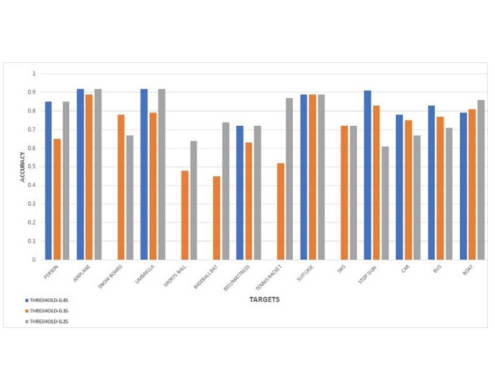

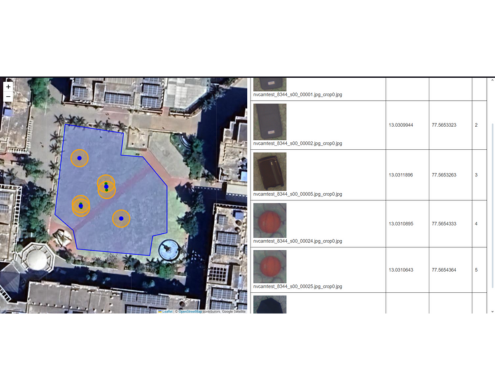

ODCL Testing

To maximize camera coverage while ensuring image clarity over the search grid, test flights are conducted. Targets are placed randomly within a 505×83 feet search grid, simulating competition conditions. The model is tested rigorously under varying light and background conditions. Geotagged images are compressed to a resolution of 800×800 pixels and processed by the model, achieving an average inference time of 2.2 seconds per image during flight. By increasing the compression to 400×400 pixels, the inference time is reduced to 1.2 seconds without compromising detection accuracy. Multiple flights are conducted with varying confidence percentages and Non-Maximum Suppression (NMS) threshold values to ensure target detection with an accuracy of 92%. Since both the manual UI and the AI pipeline utilize a common geotagging logic, Ground Sample Distance (GSD) at different altitudes is verified using the manual UI while the AI model is fine-tuned simultaneously.

The finalized configuration delivered an average localization accuracy of 89%, and a false positive rate of 11%. These tests were critical in tuning model parameters to ensure operational reliability and consistency during autonomous flight missions.

Air Drop Testing

To verify payload mechanism reliability, 20 isolated tests were conducted, all of which were successful, meeting the 9–12 second drop time. In conjunction with AI and UI systems, 100 tests followed, with 92 meeting success criteria: landing within 25 ft without payload damage. Over 90% of payload drops landed within 16 ft of the target, confirming compliance with competition requirements.

Full Mission Testing

Full mission flights are simulated under competition conditions to evaluate the integrated system and the team's preparedness. The team conducts 40 flights, each covering a total lap distance of 12 miles. Before each flight, the UAV is reassembled from a personal carry bag to a flight-ready state within 5 minutes, followed by a 15-minute setup for safety checks and waypoint plotting. Operating with minimal personnel, the flights are conducted by a safety pilot and a GCS operator. The safety pilot remains on standby to take manual control in case of system failures. The team self-evaluates the flights based on the scoring metrics outlined in the rulebook. Based on the results from the full mission flights mentioned in Table I, the team is confident in performing satisfactorily in all mission tasks.