DESIGN

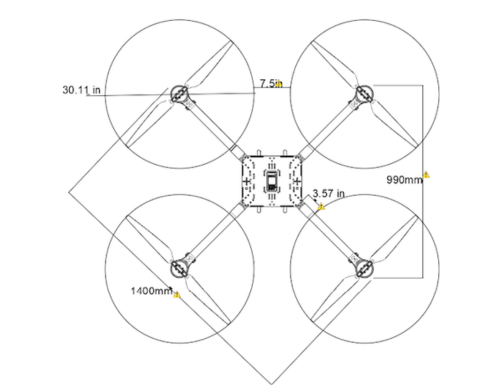

Frame Design

Engineered for the rigors of the SUAS 25 mission, the Rudra UAV frame redefines performance in a compact form factor. Despite its smaller footprint compared to conventional drones in its class, Rudra delivers exceptional power with a thrust-to-weight ratio of 3.7:1, driven by high-performance Hobbywing X8 Pro 100KV motors. This enables blistering speeds of up to 24 m/s, ensuring rapid mission execution without compromise.

Designed with efficiency at its core, Rudra’s Airframe, of 8 Kg bare weight(without payload), can be paired with a 12s 30Ah battery setup(~6 Kg), offering a versatile flight endurance of 35 to 45 minutes, adaptable to mission demands and environmental conditions.

The frame architecture balances durability, modularity, and transportability — achieving a minimized footprint that meets "design for transport" challenges while exceeding expectations in high-speed endurance, payload capacity, and future scalability. Whether racing to an objective or adapting to next-gen payloads, Rudra stands ready for today’s missions — and tomorrow’s.

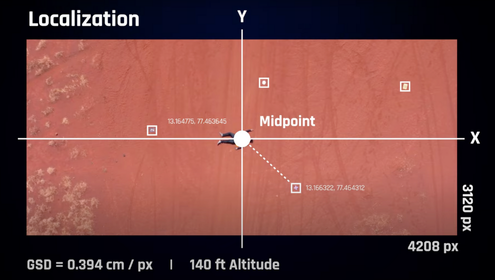

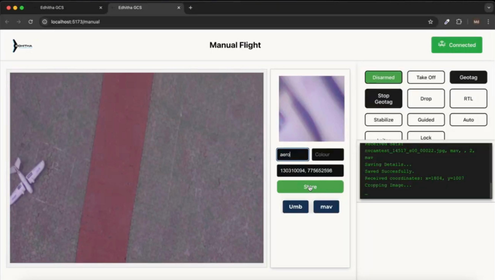

Object Detection Classification and Localisation

As the drone flies at around 5 meters per second over the search grid, it captures one image per second while the onboard GPS logs location data at 10 Hz. However, since the camera and GPS operate on slightly different timelines, we use interpolation to bridge the gap. By estimating the drone’s exact location at the moment each photo is taken — based on the nearest GPS readings before and after — we ensure that every image is precisely geo-tagged. This method results in an average positional error of less than 16 feet, providing high confidence in downstream processing.

To recognize and classify objects, we selected Grounding DINO, a cutting-edge zero-shot object detection model. Unlike conventional detectors that require extensive training with labeled datasets, Grounding DINO works immediately using natural language prompts. We've configured it to detect 15 object types such as "stop sign," "suitcase," and "snowboard" based on these simple text inputs. This approach allowed us to bypass lengthy training cycles and adapt quickly to mission-specific requirements

Once an image is geo-tagged, it’s passed to the AI model for analysis. If Grounding DINO identifies any valid targets, we determine how far each detected object is from the center of the image. This pixel offset is then converted into real-world meters using a constant called Ground Sample Distance. Using this displacement, the Haversine formula calculates the object’s exact GPS location on the ground. From there, the system autonomously repositions to the detected target and performs a payload drop — all without human input. In cases where AI misses a target due to poor lighting, unusual perspectives, or other real-world challenges, our manual fallback interface ensures mission continuity.

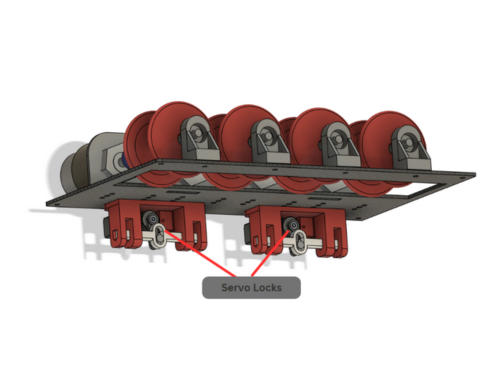

Payload Design

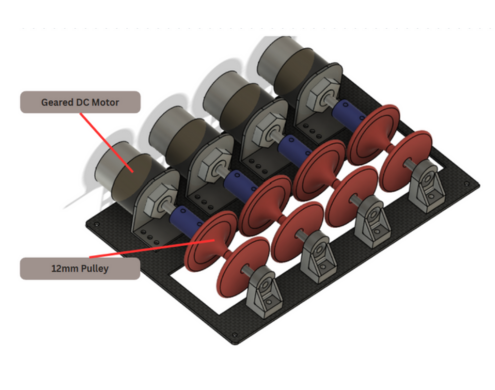

This payload system uses a simple but clever DC motor to lower items safely from a height, like a controlled zip line for packages. The motor is connected to a spool that holds a thin wire or fishing line. When the payload is released, the motor doesn’t just let it drop—instead, it uses “back EMF” (a natural braking effect caused by the spinning motor) to slow the descent, ensuring a smooth and steady fall. The speed depends on the pulley size and wire thickness—experiments showed that a 12mm pulley with a 0.5mm thread gives a safe 10-second drop, while a bigger 14mm pulley makes it too fast and risky.

| Motor RPM | Pulley Diameter | Payload Weight (g) | Drop Time (100 ft) |

|---|---|---|---|

| 500 | 12mm | 250 | 1m 13s |

| 1000 | 12mm | 250 | 9.8s |

| 500 | 14mm | 250 | 35.2s |

| 1000 | 14mm | 250 | 7s |

It’s all about tweaking with the output Torque of the motor. To keep things secure until the right moment, servo locks hold the payload in place and release it automatically when triggered by GPS or remote commands. Once delivered, the wire is discarded with the payload, making it a no-fuss, reusable system. Perfect for drone deliveries, emergency aid drops, and much more.